Leveraging your Geo-MMS for Detailed Road Surface & Infrastructure Modeling

Following the economic downturn experienced in 2020, it is expected the US will significantly increase investment over the next number of years into the country’s infrastructure (e.g. roads, bridges, etc.), becoming a key catalyst for growth regeneration in the US and global economies. With this in mind, this blog (first in a two-part series) will focus on the use-cases for leveraging Geodetics’ Geo-MMS LiDAR payloads for road surface mapping applications including identification of small cracks, potholes and road-surface anomalies.

A strategic documentation plan for all road networks is more economically attractive than implicit ignorance of the situation. 3D scans of the full transport environment feed into other important infrastructure inspections, including assessment of pavement conditions, bridge monitoring/inspection, roadside powerline assessment, and more.

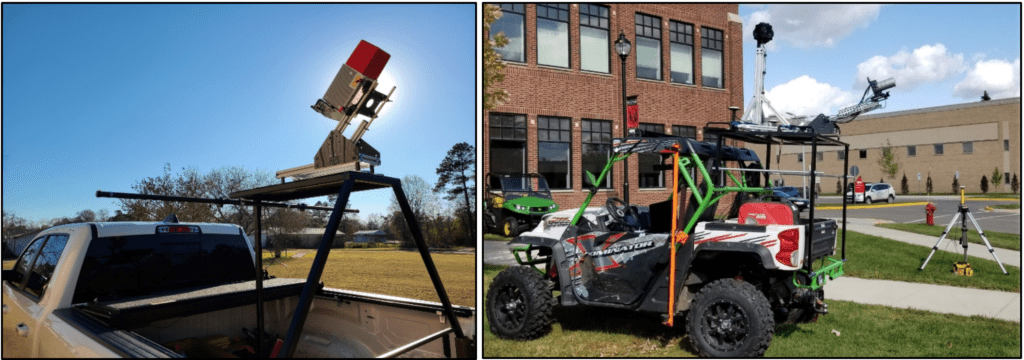

Geodetics’ customers have leveraged the power of their LiDAR mapping systems for use on ground-vehicles for many years. These include cars, all-terrain vehicles (ATVs) and rail-modified platforms (as shown below). Learn more about the applications of rail-modified platforms from a previously published blog. Geodetics has developed ground-vehicle mounting assemblies designed to accommodate all Geo-MMS LiDAR payloads. These mounting brackets are designed to be flexible, like the payloads they carry, and can be installed on virtually any moving vehicle.

Figure 1. Survey-grade raster scanning LiDAR sensor, installed on a modified Geo-MMS ground-vehicle mounting assembly (left – Access Surveyors) and Geo-MMS 32-channnel tactical-range LiDAR with 360° spherical imaging camera integrated for off-road mapping (right – Precise Sensing).

Mobile LiDAR Scanning in Practice

For road surface mapping, the sensor should be elevated and orientated such that it scans the road surface and the surrounding terrain/features in a full 360° frame. While all LiDAR sensors integrated by Geodetics can be integrated on ground-based mobile platforms, recent demand has specifically been targeted towards our high-end survey-grade raster scanning LiDAR sensors. The unrivaled precision, accuracy, and point density of these sensors make them ideally suited to capturing and documenting cracks and distresses on roads, which may not be captured by spinning analog LiDAR sensors. The heavier weights of these sensors are not a concern for ground-based mobile mapping, unlike their effects on flight time when mounted to a UAV. The cm-level resolution offered by these sensors is frequently sought by those aiming for the highest accuracy possible for road surface mapping.

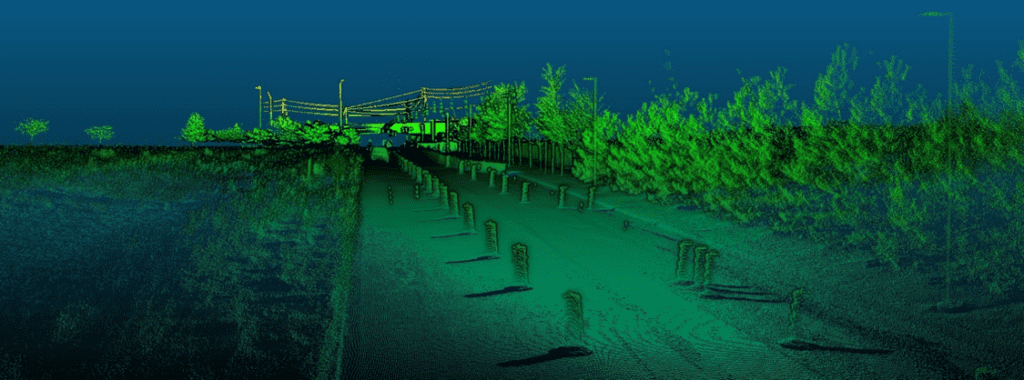

One of the many advantages of mobile road scanning, as stressed previously, is the rapid and efficient identification of small cracks, potholes and road surface anomalies. The point density achieved with high-performance systems allows the user to scan at regular highway speeds, allowing vast datasets to be collected in a fraction of the time as traditional methods, all while improving positional data accuracy and increasing safety. Reflectivity characteristics of road markings, road signs, and railings along transport routes allow them to become pronounced when viewing the collected LiDAR datasets by the intensity of the raw LAS files.

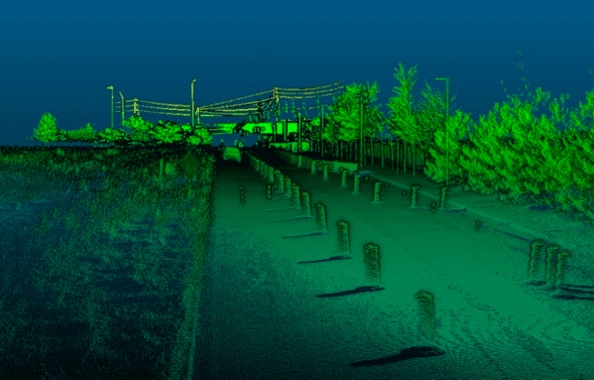

Figure 2 below displays data captured with the CL-360 LiDAR from Teledyne Optech. The key to collecting such high-quality point clouds lies in optimizing a balance between sensor scan line frequency, PRF (Pulse Repetition Frequency), and vehicle speed. For the highest point density, we can select the maximum capabilities of 250 scan lines per second and a 500 kHz PRF. Vehicle speed will then ultimately determine LiDAR point density. Using the full FOV available, we can detect all features of interest on the road and surrounding terrain.

Actionable Data

Assessment records of roads and their associated assets are increasingly needed in formats native to GIS and CAD programs. LiDAR scanning introduces unmatched levels of dimensional accuracy, scan feature richness and efficiency of data capture. Capturing LiDAR scan data along road and rail transportation corridor routes can generate terabytes of point cloud data. An efficient process to manage the captured data, assess its quality and extract the desired information is necessary to seamlessly feed downstream planning, design, engineering and construction operations.

Captured scan data can be meshed in post-processing software to produce a 3D structure of any detected anomalies. The 3D nature of the scan data also allows point cloud sections to be inverted and viewed from the bottom, something not possible with imagery alone. A basic example is shown in Figure 3 below, with meshing performed with open-source point cloud processing software.

In part two of this blog series, we will dive further into the role of mobile LiDAR scanning on road and infrastructure projects along with the role RGB imaging (as seen in Figure 1) plays in the overall mapping ecosystem and workflow.

Originally published by Geodetics