LiDAR Systems: A Guide to Understanding LiDAR Sensors Function and Capability

Let’s talk about the various metrics used when discussing Geo-MMS LiDAR sensor characteristics – and how do we sort through the overwhelming information provided by LiDAR sensor manufacturers?

LiDAR Systems: Sensor Range and Precision

The range of a LiDAR sensor is often one of the key characteristics highlighted in any information you receive regarding that sensor. The sensor range is tested under laboratory conditions and is presented as the maximal range at which detection can be captured. For effective mobile mapping, however, the effective range is significantly less than the nominal range stated in a manufacturer’s datasheet. To simplify, we group mobile mapping range into three categories: tactical, mid-range and long-range.

Accuracy and precision are two different statistical concepts.

- Accuracy measures how close a range measurement (mean) is to the true distance of an object.

- Precision measures how repeatable are identical consecutive measurements to each other.

For 3D mapping cases, precision is critical for point cloud ‘crispness’ in the form of clean corners and defined features. Lower precision can result in fuzziness in the generated point clouds, making it difficult to discern important features.

LiDAR Systems: Sensor Ruggedness

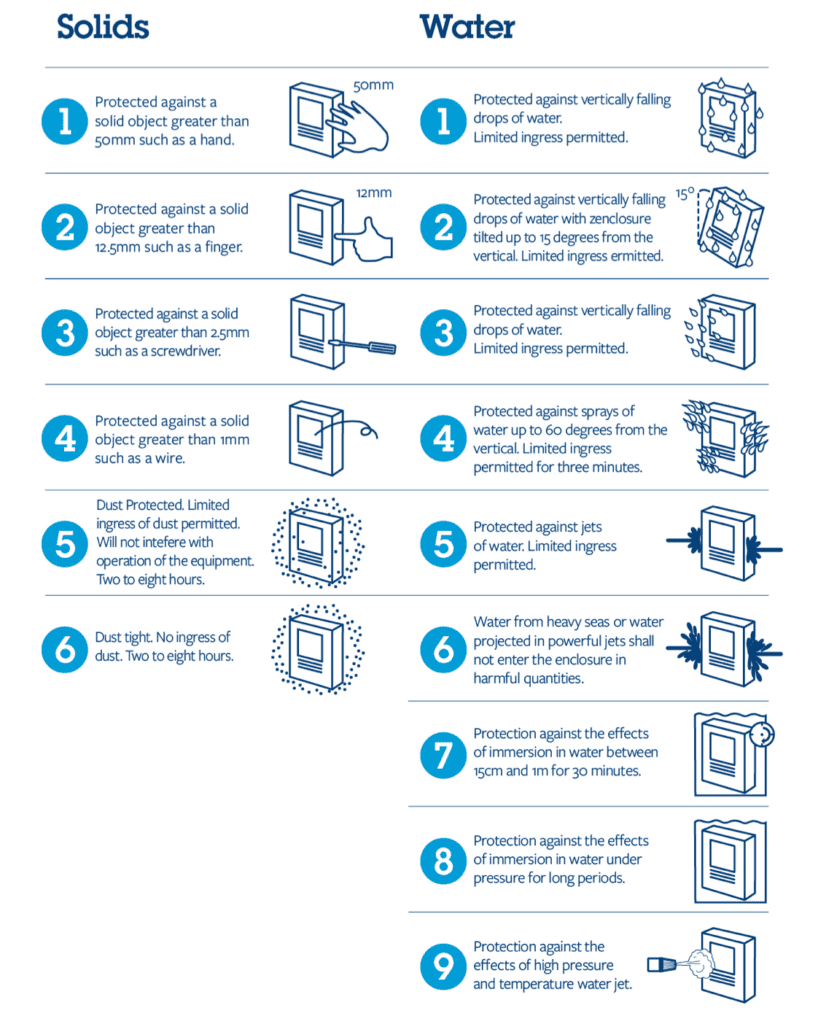

The Ingress Protection Code (IEC 60529) provides guidance on a sensor’s resistance to ingress from particles such as dust and water.

- The first digit represents resistance to dust (1-6) – 6 is the most resistant

- The second digit represents resistance to water (1-9) – 9 is the most resistant

- Spinning sensors generally have the highest IP ratings (IP67 to IP69K)

- Raster scanning systems will typically have a slightly lower rating (IP65 to IP67)

LiDAR Systems: Sensor Architecture & Laser Type

In this series of blogs, we have broadly separated UAV-LiDAR sensors into two groups – spinning LiDAR and raster scan LiDAR systems. The system architecture of these two categories are fundamentally different. Raster scan sensors are the only kind that can be considered truly survey-grade. They were designed and developed for this function. These sensors possess higher return capabilities, giving them a distinct advantage for LiDAR mapping over the foliage.

Spinning LiDAR sensors were primarily developed for autonomous vehicle applications and robotics. Their usefulness also extends to affordable 3D mobile mapping. Installation on an autonomous vehicle illustrates the need for the highest level of Ingress Protection – to protect from power washing and exposure to harsh elements. The advantage of being lightweight and low-cost is attractive to many pursuing UAS-LiDAR projects. However, those achieving survey-grade accuracy and precision should always opt for a raster scan LiDAR sensor.

Spinning sensors typically utilize Edge Emitting Laser Diodes (EELD) while Raster Scan systems utilize a Fiber-Pulsed Laser. EELD lasers are a mature technology and offer reliable all-around performance. These sensors typically operate at the ~905 nm wavelength. Sensors with 600-1,000 nm wavelengths are not suitably safe for human eyes as the laser light can be focused and absorbed by the eye. As a result, sensors that operate in this wavelength have their power limited or capped to be in-line with safety regulations.

Fiber lasers are generally more expensive, power-hungry and operate at the ~1,550 nm wavelength. A 1,550 nm wavelength is eye-safe, so sensors with this wavelength can operate at high/full power. Because of this, they can be utilized at higher AGL altitudes. By allowing the operation of more powerful lasers without violating eye-safety regulations, it has a positive impact on the maximum achievable range. Sensor manufacturers who utilize 1,550 nm do so in order to pump a lot of power into the sensor.

Choosing the correct LiDAR sensor for your application and budget is an essential stage in setting up your UAV or mobile mapping system. For any questions relating to LiDAR sensors or your project in general, Request more Information. Already know the ideal sensor for your use-cases? Request a Quote today!