Understanding the Role and Impact of Each on your UAV-LiDAR Missions

This blog (second in a two-part series) continues our explanation of the variables which influence boresight calibration and strip alignment when flying drone-based LiDAR missions. If you missed the first part of this series, we recommend you check it out before continuing with this blog.

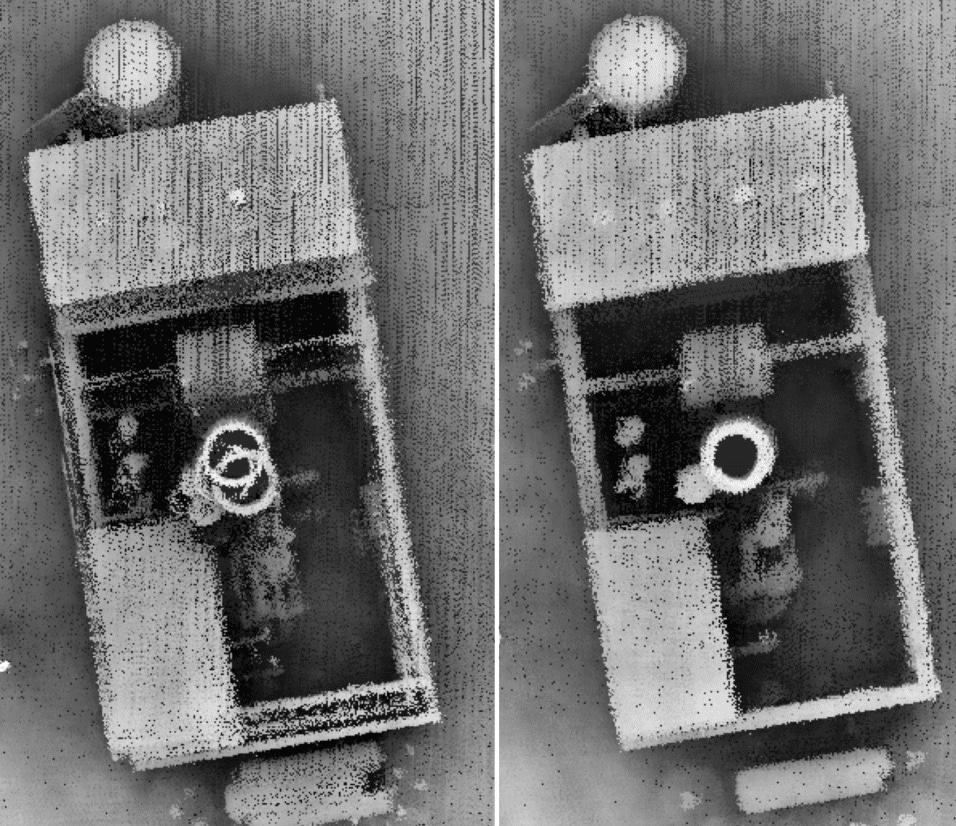

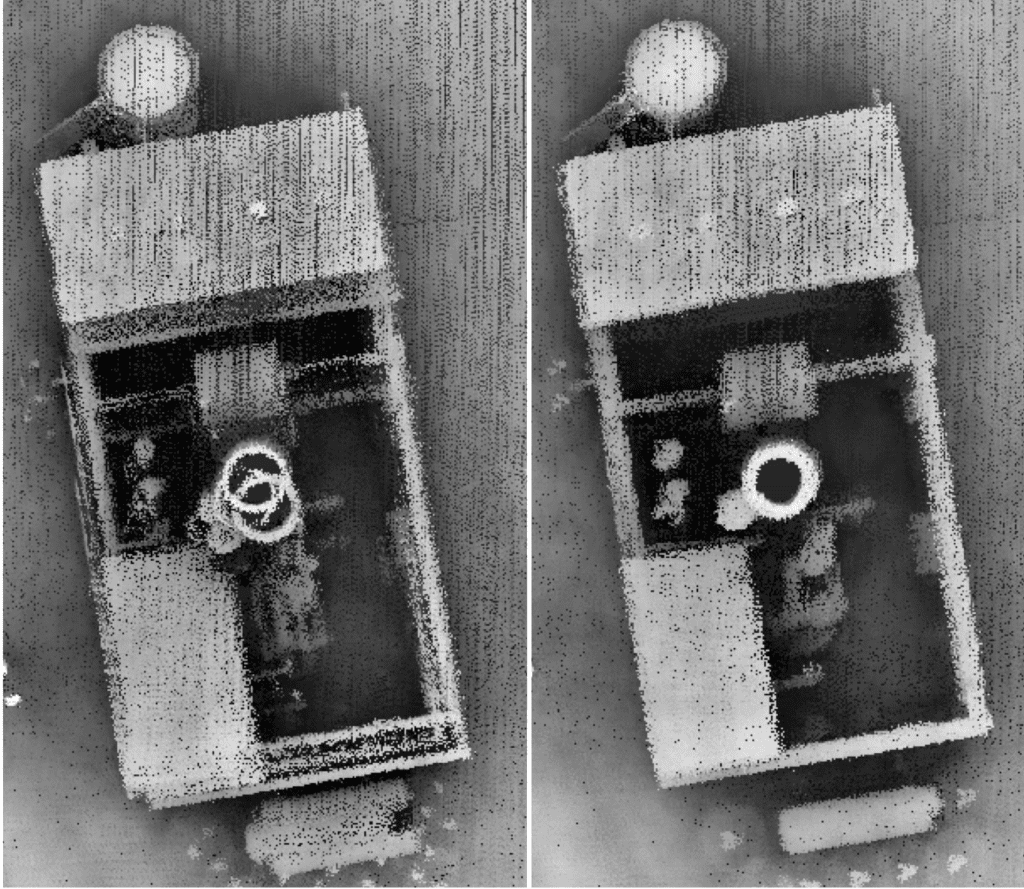

LiDAR boresight calibration aims to calibrate the LiDAR boresight angle, as demonstrated in Figure 1 below. Boresight calibration addresses the issue of alignment of the LiDAR and the IMU body frames – the correlation between the LiDAR boresight angles and the INS attitude. Some specialized third-party software can decorrelate these two error sources and estimate/calibrate the LiDAR boresight angles. However, some software developers list these capabilities but simply lump all errors together and employ automated algorithms to align the point clouds.

Figure 1. LiDAR boresight calibration – before (left) and after (right

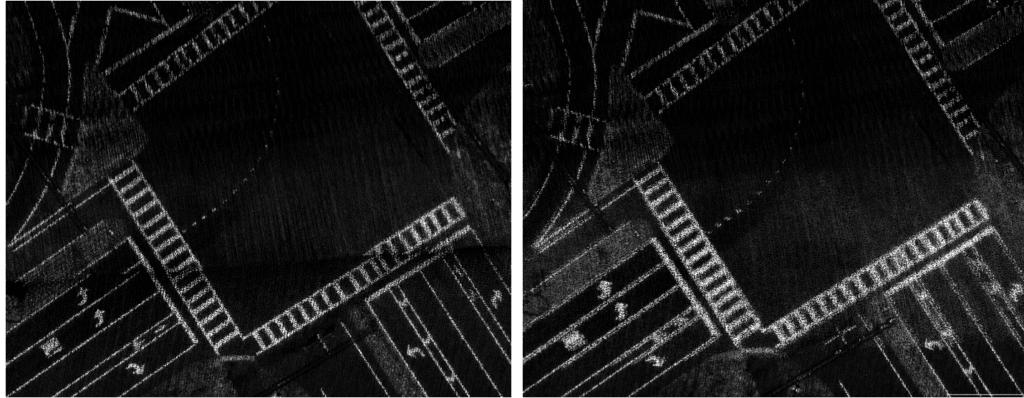

Strip alignment (also known as strip adjustment) can help improve the consistency between several adjacent UAV-LiDAR flight lines. Strip alignment workflows utilize algorithms which align the LiDAR point clouds from one strip to another without necessarily knowing the source of the error. Certain LiDAR post-processing software options will have built-in capabilities for strip alignment. These ensure alignment of the point cloud based on common features captured in overlapping data sections and computing the geometric transformation between these datasets. Addressing boresight error is typically the first step in the strip alignment workflow.

Strip alignment procedures can be used if the system has undergone boresight calibration but there are remaining residual discrepancies in overlapping areas that cannot be explained by other sources of error. In other words, strip alignment is only necessary if there are still minor misalignments noticeable after the LiDAR point cloud has been georeferenced. Factors such as flight altitude profile, manual flight, wind or other environmental conditions can impact the flight trajectory in subtle ways that keep the point clouds from aligning as intended.

As another example, let’s consider flying a Geo-MMS LiDAR payload over a construction site. We fly the mission, collect and process the data and visualize it in our 3D point cloud viewer. Upon visual inspection, we see two lines in the point cloud for a feature we know should only be represented by one line (e.g., edge of a building roof). This may have been the result of poor flight planning and execution, inexperienced piloting or flying in harsh weather conditions. If you are on a tight schedule, strip alignment software can make a positive difference by offering different options to improve the consistency between flight lines. Different algorithms can correct the position and angles of the drone across the mission duration to align the data as it was intended to be collected originally. Post-processing the data in this fashion can save time by avoiding a repeat mission.

Figure 2. Misalignment of adjacent LiDAR strips intersecting a feature of interest (left) and with automated strip alignment algorithms employed (right).

In the example described above, the alternative to owning strip alignment software would be a repeat mission (correct planning and execution in better flying conditions). Repeating a mission as a one-off is fine, but users who regularly have to re-fly missions may stand to benefit from a dedicated point cloud strip adjustment software.

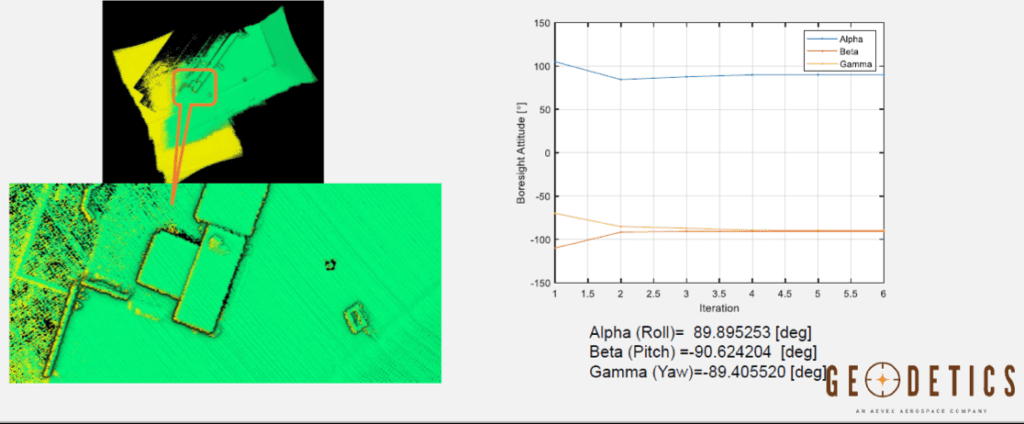

Software such as BayesStripAlign from BayesMap Solutions focus on automated strip alignment for LiDAR point cloud data from UAVs and manned aircraft. If correct flight planning and execution are adhered to, it is rarely necessary to add this level of capability to UAV-LiDAR post-processing, given the onboard INS is of the highest quality. Specialized software can be useful when performing work at high altitudes from manned aircraft with long-range sensors such as the Teledyne Optech CL-360XR. For LiDAR pilots who are forced to operate in harsh conditions (something we advise against), a strip alignment software can help correct for the environmental impacts exerted on your data collection methods. However, most software have limited support for UAV-LiDAR operations. The most practical approach is to avoid operating the system in harsh weather, in which all sources of the aforementioned error sources will exceed normal ranges. To counter this, Geodetics developed a set of algorithms that can adaptively adjust the boresight angles for each individual LiDAR strip, eventually aligning all strips together. The figure below demonstrates system operation from aligning two sets of overlapping point clouds based on adjustment of the boresight angles. The algorithm converges rapidly and estimates accurate misalignment angles. Future developments will extend this algorithm to more generic cases of data collection scenarios in which the AOI is primarily featureless terrain.

Figure 3. Example is taken from Geodetics’ boresight angle adaption software.

Geo-MMS customers can rest assured knowing that the proprietary Defense-grade inertial navigation technology developed by our navigation scientists and engineers is amongst the highest quality in the industry.

Originally published by Geodetics